Single catalyst pellet reactor

- Post by: Thomas Chamberlain

- April 15, 2020

- Comments off

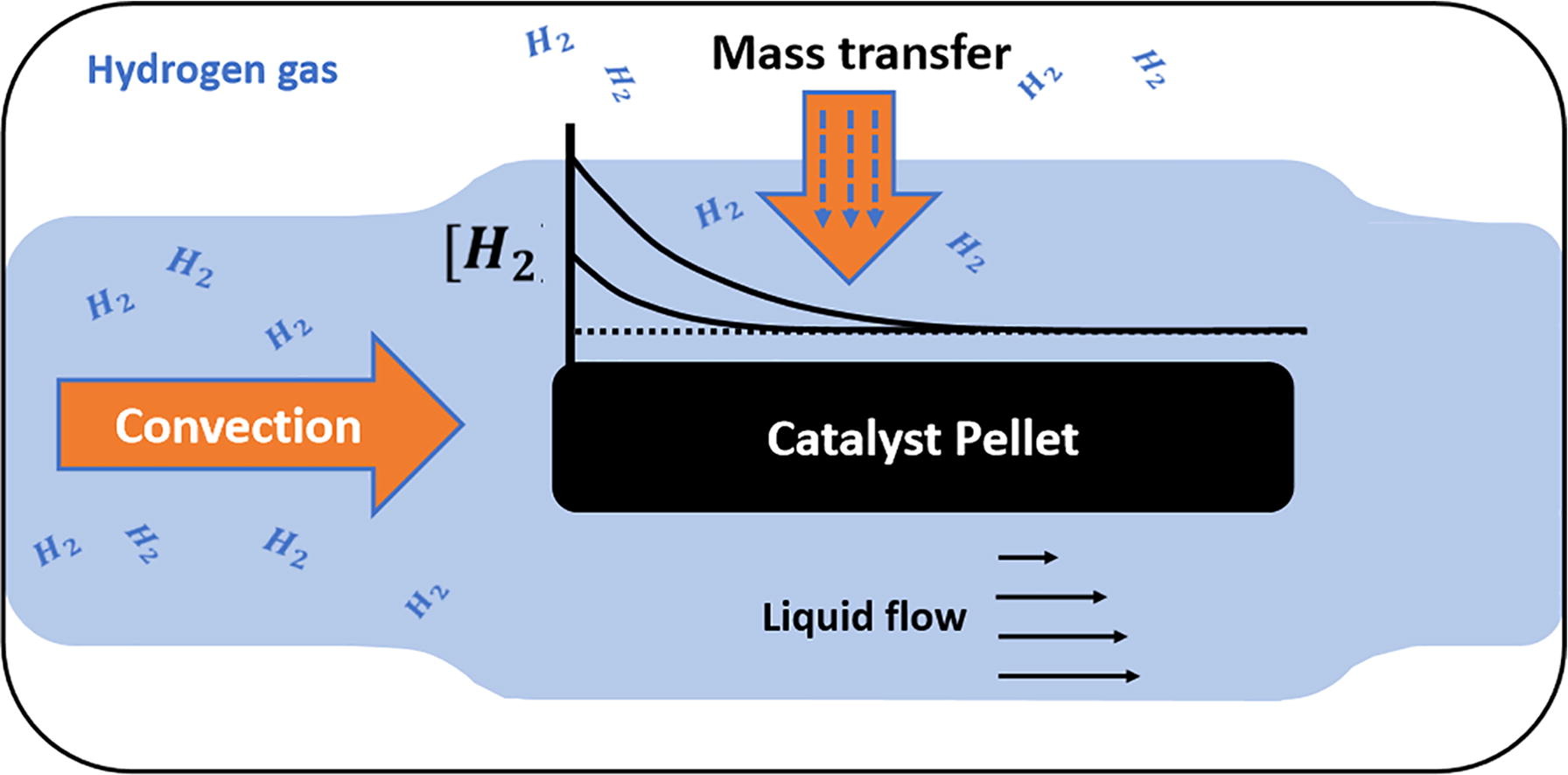

Trickle bed reactors offer a viable alternative to batch manufacture, however further understanding of the interplay between hydrogen mass transfer and catalytic reaction is required to facilitate the uptake of such technologies.

Our recently published paper, see below, outlines how we isolate these transport processes. The hydrogenation of styrene was conducted with a single 1% palladium on carbon pellet immobilized within glass beads with a liquid feed either hydrogen saturated or hydrogen free and the liquid flow rate was varied. The transfer rate of hydrogen was found to be significantly affected by the hydrogen content in the feed. The observations are well described by a new model in which the pellet film is treated as a plug flow reactor, with mass transfer from the gas phase to the film modelled as diffusion through a stagnant film, and mass transfer from the film to the catalyst surface and the subsequent reaction modelled as resistances in series.

Our findings indicate that the provision of inert mass transfer area to saturate the fluid with hydrogen can significantly increase the productivity per unit mass of catalyst. In addition, by controlling the ratio of catalytic and inert surface the hydrogen concentration close to the catalyst surface can be tuned. This could be utilised to adjust both the activity and selectivity of the system and therefore, give trickle bed reactors an advantage in chemical manufacturing processes.

Link to article – Decoupling the relative rate of hydrogen uptake via convection and mass transfer by a single catalytic pellet in a scaled down trickle bed reactor.